Copper & Alloys

H. Cross Company is one of the largest suppliers of Copper and Copper Alloy in all forms including wire, strip, ribbon, sheet and foil.

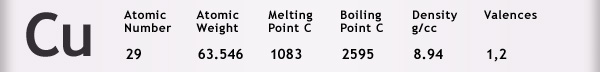

Type 101 Copper

Type 25 Beryllium Copper Alloy

Cupro-Nickel Alloy 715

Type 101 Copper

Type 101 – also known as Oxygen-Free Electronic (OFE). This is a 99.99% pure copper with 0.0005% oxygen content. It achieves a minimum 101% IACS conductivity rating. This copper is finished to a final form in a carefully regulated, oxygen-free environment. Silver (Ag) is considered an impurity in the OFE chemical specification.

| Annealed | As Rolled | |||

| Ultimate Tensile Strength | 35,000 PSI | 57,000 PSI | ||

| Yield Strength | 10,000 PSI | 53,000 PSI | ||

| Elongation | 40% | 2% | ||

| Modulus of Elasticity | 17 x 10e6 PSI | |||

| Poisson’s Ratio | 0.32 |

| Density | 0.323 lbs/cu in | |

| Melting Point | 1080° C | |

| Electrical Resistivity | 101% IACS @ RT | |

| Temperature coefficient of Resistivity (0 to 100° C) |

3900 PPM/°C | |

| Electrical Conductivity @ RT | 586 Megmho-cm | |

| Thermal Conductivity @ RT | 390 W/m*k | |

| Thermal Expansion Coefficient | 17 x 10e-6/ °C | |

| (20 to 100 °C) |

Applications

Used for electrical and electronic conductors, wave guides, cavity resonators, superconductor matrixes, vacuum tube and solid-state devices, and glass-to-metal seals.

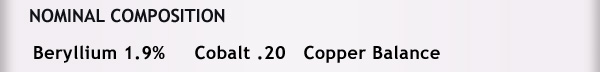

Type 25 Beryllium Copper Alloy

Beryllium Copper #25 is a copper based alloy that can be strengthened by precipitate hardening. This alloy combines the best combinations of electrical conductivity, corrosion resistance and mechanical strength making it ideal for numerous electronic and electro-mechanical devices.

| Annealed | Annealed Precipitate hardened |

As Rolled | As rolled Precipitate hardened |

|||||

| Ultimate Tensile Strength (PSI) |

70,000 | 175,000 | 120,000 | 210,000 | ||||

| Yield Strength (PSI) | 30,000 | 150,000 | 110,000 | 200,000 | ||||

| Elongation | 35% | 3% | 2% | 1% | ||||

| Modulus of Elasticity | 18.5 x 10e6 | |||||||

| Poisson’s Ratio | 0.285 |

** These values are general in nature and can be altered by control of different process variables. H. Cross can supply this material in a wide range of tempers and elongations.

| Density | 0.298 lbs/cu in | |

| Melting Point | 865° C | |

| Electrical Resistivity @ RT | 7.81 Micro Ohm-cm | |

| Thermal Conductivity @ RT | 105 W/m*k | |

| Thermal Expansion Coefficient | 17.5 x 10e-6/°C | |

| (20 to 200 °C) | 0.128 Megmho-cm (Hardened temper) |

H. Cross Company can supply these products in all forms including wire, strip, ribbon, sheet and foil. We can also produce these materials in round, slit or square edges depending on your size requirements. See our standard dimensional sizes and tolerances for more information. If you do not see the size range you are interested in please Contact Us by email or phone us with your specific requirements.

Cupro-Nickel Alloy 715

Cupro-Nickel Alloy 715 is a copper nickel alloy with resistance to corrosion in salt water. It has good fatigue strength and thermal conductivity.

| Annealed | As Rolled | |||

| Ultimate Tensile Strength | 65,000 PSI | 100,000 PSI | ||

| Yield Strength | 35,000 PSI | 90,000 PSI | ||

| Elongation | 30% | 2% | ||

| Modulus of Elasticity | 22 x 10e6 PSI |

| Density | 0.322 lbs/cu in | |

| Melting Point | 1170° C | |

| Electrical Resistivity @ RT | 41.2 Microhm-cm | |

| Thermal Conductivity @ RT | 29.4 W/m*k | |

| Thermal Expansion Coefficient | 15.5 x 10e-6/°C | |

| (20 to 95 °C) |

H. Cross Company can supply this product in all forms including wire, strip, ribbon, sheet and foil. We can also produce these materials in round or slit edges depending on your size requirements. See our standard dimensional sizes and tolerances for more information. If you do not see the size range you are interested in please Contact Us by email or phone us with your specific requirements.